Ramset screws failed her gallery wall — now she swears by metal anchors for peace of mind.

Share

When Wall Plugs Fail and Picture Frames Fall: Mount Heavy Items the Right Way

Got a brick wall and a bold idea? Here's how to make it hold — safely.

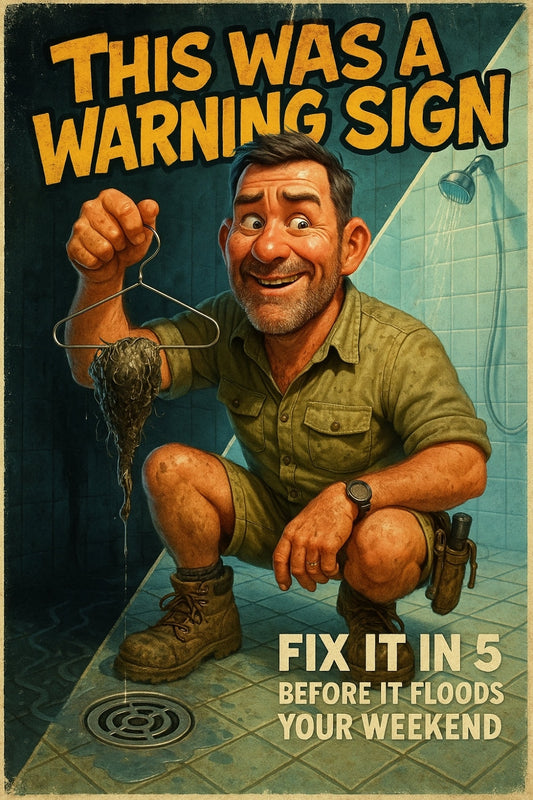

It happens more than you'd think. You're proud of that beautiful mirror or floating shelf — until one day, it crashes to the floor. And all you used were the plastic plugs from the back of the packet. Oof.

Here’s the real talk: The difference between ‘still standing’ and ‘smashed on the floor’ is often the anchor you can’t see.

From wedding photo walls to smart TV installations, heavier home additions need stronger support. And whether you’re working with brick, plasterboard, or the odd horsehair-render panel (yes, we’ve seen it), choosing the right anchor and screw setup isn’t just handy — it's non‑negotiable.

What changed when one customer switched their anchors?

Before: Their vertical garden frame was up for one week before disaster struck. Screws pulled clean out. Soil and succulents down the driveway.

After: Using the right masonry screws and hollow wall anchors — still standing straight after last spring’s hallway earth tremor (true story).

First, know your wall like you know your kettle

Not all walls are created equal. Before buying any fixings, answer this:

- Is it solid? (Brick, stone, concrete — you’ll hear the thud.)

- Is it hollow? (Gyprock/plasterboard — lighter knock, more bounce.)

- Is it unpredictable? (Older horsehair plaster, double brick retrofits, lathe-and-plaster — handle with care.)

Each wall type needs different hardware. Get it wrong, and you’ll shear off screws or split boards. Get it right, and your item becomes part of the home.

The 4 anchor types every DIYer should know

1. Toggle bolts (for hollow walls)

The spring-loaded wings spread behind your gyprock, gripping like a claw. Good for larger loads — think big clocks, shelves, indoor plant brackets.

2. Wall mates or self-drilling anchors (for plasterboard)

Twist straight in with a drill or screwdriver. Ideal for lighter jobs up to 10kg — photo frames, coat hooks, bathroom accessories.

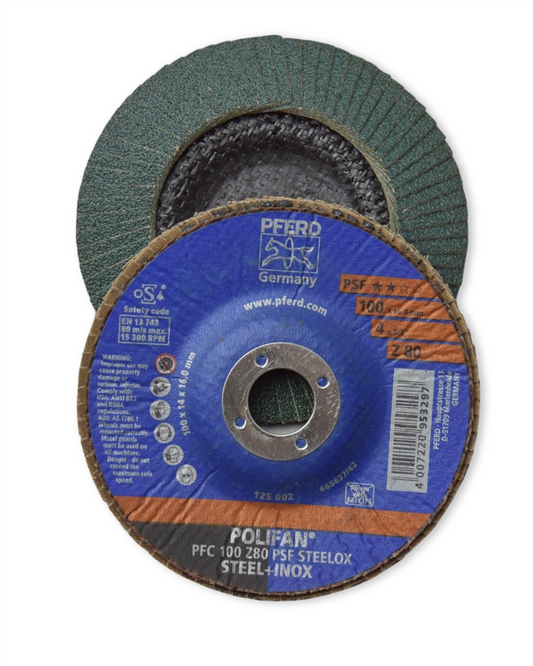

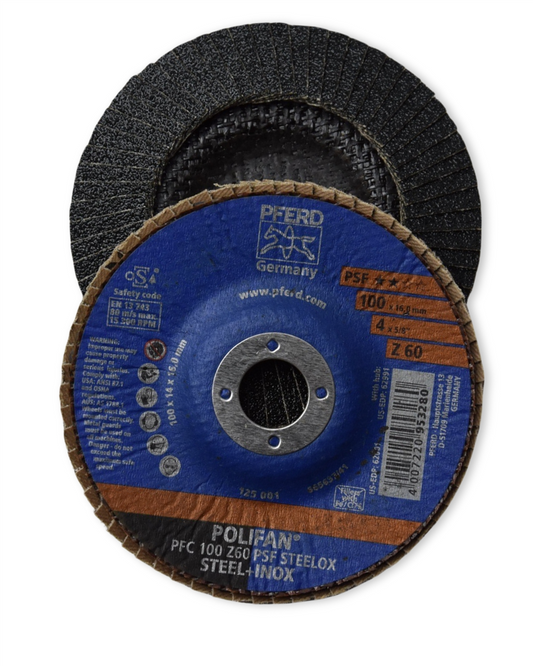

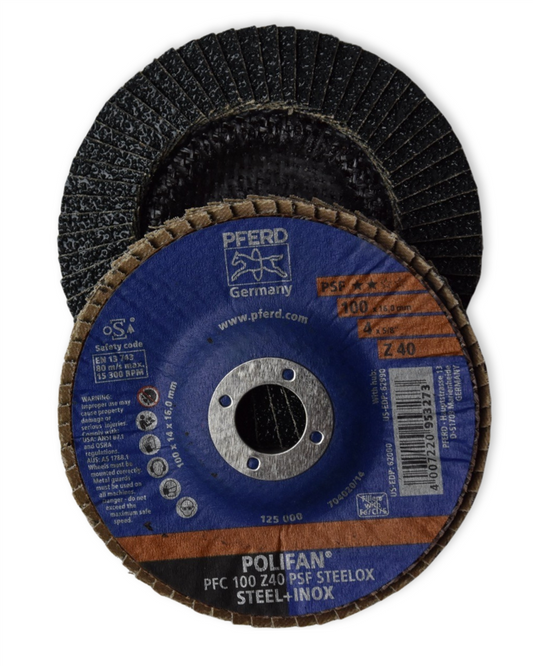

3. Metal sleeve anchors (for solid concrete/brick walls)

Drill a hole the size of your anchor. As the screw drives in, the sleeve expands — gripping tight in masonry. Bulletproof (well, nearly).

4. Masonry screws (like Torx or concrete screws)

No plugs needed. Lag into brick or concrete for serious strength. Great for outdoor mounting, thick timber frames, or tool storage walls.

Match your anchor to the job

Here’s a simple chart you can screenshot, save, or stick on the shed wall:

- Hanging Pictures/Art (up to 5kg): Self-drill wall mates

- Corner Shelves/Book Ledges (6-12kg): Toggle bolts or nylon toggles

- Floating Vanity Mirror (15kg+): Masonry anchors into studs or brick with appropriate screws

- TV Brackets/Indoor Bike Racks (20kg+): Sleeve anchors or concrete screws into solid walls

Still not sure? Grab a magnet. If it finds studs (metal screws or nails) behind your wall, you may not need anchors at all — go straight into that frame.

The anchor myth that sends projects sideways

“Stronger screws mean stronger mounts” — not true. The anchor holds the wall, not the screw. The screw connects your hardware to the anchor. If the wall cracks or crumbles, it doesn’t matter how shiny your fastener is.

This is where people go wrong: they size up the screw and forget the surface it’s going into. The wall fails before the metal does.

Small effort now, big confidence later

You don’t need a workshop of tools or years of experience. You just need patience, the right drill bit size, and a steady anchor system matched to your load. And if you're unsure — bring a photo of your wall, the weight of your item, and we’ll guide you through step-by-step in-store.

Want a weekend win you’ll still be smiling about in six months? Start from the back — the right screw + the right anchor = no surprises.

Wall anchors aren’t exciting. Until they save the mirror, the tiles and your toes.

Cheers,

Candeece

Stay Connected

Follow our Facebook Page: Strathalbyn H Hardware on Facebook