Pick the wrong drill bit, and your project bites back — here’s how to choose right

Share

Picking the Perfect Drill Bit — Without the Guesswork

Not all drill bits are cut from the same cloth. What slices right through timber might wither against a concrete wall or end up glowing red on steel. Choosing the wrong bit doesn’t just leave you with a half-done hole and a toasted tool — it can mean busted projects, wasted afternoons, and expensive do-overs.

This is your no-nonsense guide to choosing the right drill bit — built for real folks who’d rather get things done than Google all day.

What Exactly Makes a Drill Bit ‘Right’ for the Job?

It comes down to three things: material, tip design, and your target surface. Each bit is designed to handle certain materials without slipping, dulling, or overheating. Think of it like choosing tyres — you wouldn’t take racing slicks onto a muddy paddock. Wrong match, wrong result.

1. For Timber — Smooth, Quick, and Clean

Drilling into softwood or hardwood? You’ll want a bit that bites into the grain fast and exits clean. These are your best bet:

- Brad Point Bits: These have a little spur at the tip that anchors the bit as it starts. Ideal for precision and clean holes in timber.

- Spade Bits: Great for fast, large holes — like running wiring or pipes through studs. Rugged, but they can roughen up the edges a bit.

- Auger Bits: Think deep and slow. Ideal for big bore holes in hardwoods, especially fencing or framing work.

Pro tip: If you’re drilling pilot holes for screws, match your bit to the shank diameter — and maybe go slightly smaller to keep grip tight.

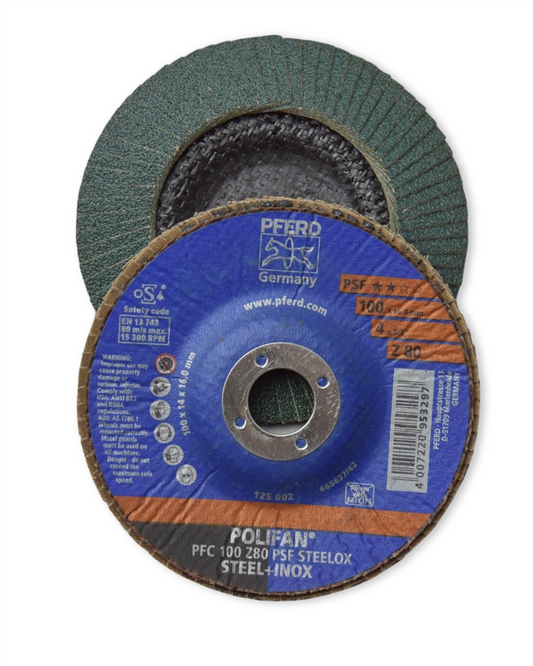

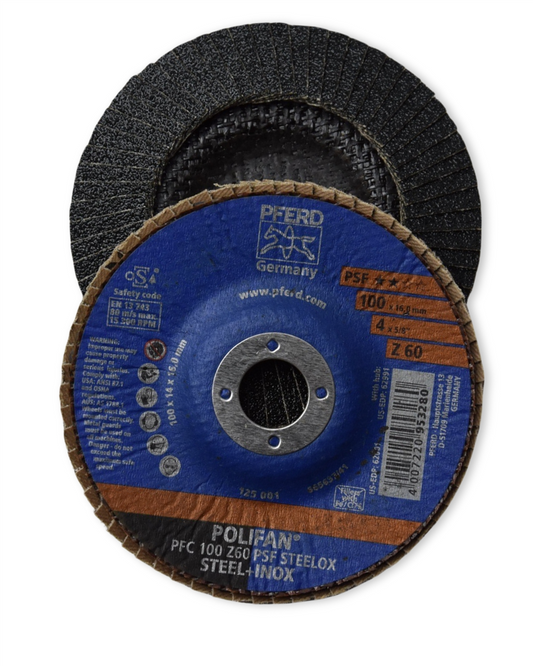

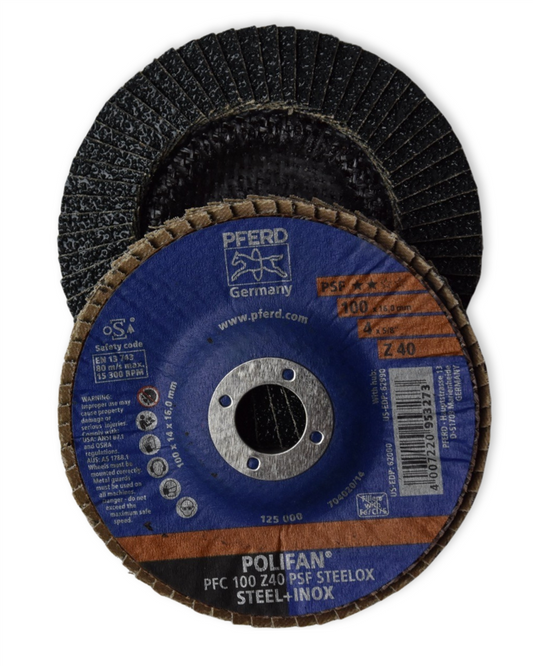

2. For Metal — Strong, Steady, and Cool

Metal fights back. If you’re drilling into steel, aluminium, or galvanised pipe, your bit needs to be up for the challenge. Look for:

- High-Speed Steel (HSS) Bits: These are your general go-to for most metals — affordable and reliable, best for lighter tasks.

- Titanium-Coated Bits: More durable and heat-resistant, these glide through metal like a hot knife in butter — without burning out so quickly.

- Cobalt Bits: When you’re tackling tough stainless steel or thicker gauge materials, these are the top tier. Slower and pricier, but built to last.

Safety callout: Always clamp your workpiece and drill at low speed with cutting fluid. That keeps heat down and stops bits from going blunt too fast.

3. For Masonry — Tough, Gritty, and Shock-Resistant

Brick, concrete, stone — masonry doesn’t mess around. Neither should your bit. Here’s what works:

- Masonry Bits: These have a rugged, arrowhead-style tip often made of tungsten carbide. They're built to chip into stone thanks to their hammer-tough tip and fluted bodies.

- SDS Bits: If you’re using a rotary hammer or hammer drill, SDS bits lock in and get serious. Perfect for deeper holes in concrete and commercial building projects.

Hear this line once, and it’ll stick for life:

“No hammer drill? No masonry bit. It’s like trying to chop firewood with a butter knife.”

Still Unsure? Here's a Quick Glance Cheat Sheet:

| Surface | Best Bit Type | Drill Speed |

|---|---|---|

| Timber | Brad Point / Spade / Auger | Medium to High |

| Metal | HSS / Titanium / Cobalt | Low |

| Masonry | Masonry / SDS | Low with Hammer Function |

Troubleshooting: When Your Drill Bit’s Not Biting

Is your drill bit just spinning and squealing with nothing to show for it? That’s your cue. Could be you’re using the wrong bit, dull gear, or missing the right settings. Always check:

- Is your drill set to the right mode? (Hammer for masonry, regular for wood or steel)

- Are you leaning too hard? Let the bit do most of the work – it’s not a punching contest.

- Is your bit still sharp? A dull bit is more dangerous than a fast one.

Final Thought: The Right Tools Speed the Job — And Save The Headache

The perfect drill bit doesn’t just make holes — it clears the path for every screw, anchor, and bolt that follows. And if you’ve ever snapped a fastener halfway into a dodgy hole, you already know why that matters.

At the end of the day, getting the right bit for the job saves your arms, your wallet, and your patience. So, when in doubt, ask someone who knows the gear inside out — not just what's on the shelf, but what works in real-world builds, in this region, with your kind of deadlines breathing down your neck.

Here’s to fewer mis-drills and cleaner cuts across your projects — big or small.

Catch you in the aisles,

Candeece

Stay Connected

Follow our Facebook Page: Strathalbyn H Hardware on Facebook