How to Master Your First Angle Grinder Cut Without Risking Injury

Share

Mastering Your First Cut: A Local’s Guide to Confident, Safe Angle Grinder Use

Bosch tools in hand, you’re ready to prove you’ve got the DIY grit—but is your first cut setting you up for a win or a trip to the ER?

A clean slice through steel feels powerful—until the sparks fly a bit too close. Knowing how to tame that energy not only keeps your fingers safe but also gives you the confidence to take on bigger jobs without flinching. One of our regulars admitted his first angle grinder attempt sent sparks across the lawn; now, after learning a few tricks, he finishes metal gates in minutes. That’s the gap between guesswork and good guidance.

Why Angle Grinders Deserve Respect

An angle grinder might look small, but it holds serious muscle. These tools spin cutting or grinding discs at 10,000+ revolutions per minute—enough to bite through steel, tile, concrete, or wood faster than you can blink. That means there’s no room for casual handling.

Still, used right, an angle grinder is a mate for life in your toolkit. From trimming rusty bolts to cutting fence posts, prepping old paint, or shaping stone pavers, it’s one of those tools that makes tough jobs suddenly simple. The trick is balancing precision with protection.

1. Gear Up Like a Pro

You wouldn’t cook bacon bare‑armed—same logic here. Before you pull the trigger, make sure you’re wearing:

- Eye protection: A face shield or safety glasses rated for impact.

- Gloves: Snug, not loose. They keep your grip steady.

- Hearing protection: Grinders bark louder than a kelpie during thunder.

- Long sleeves and sturdy boots: Sparks travel; cotton or leather wins over synthetics every time.

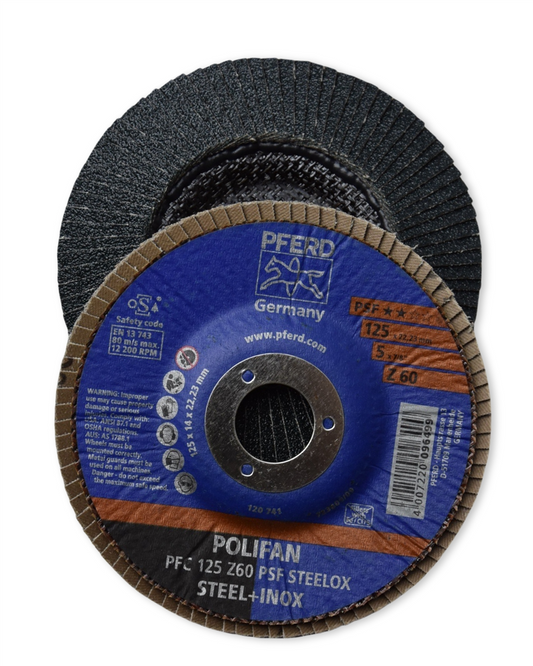

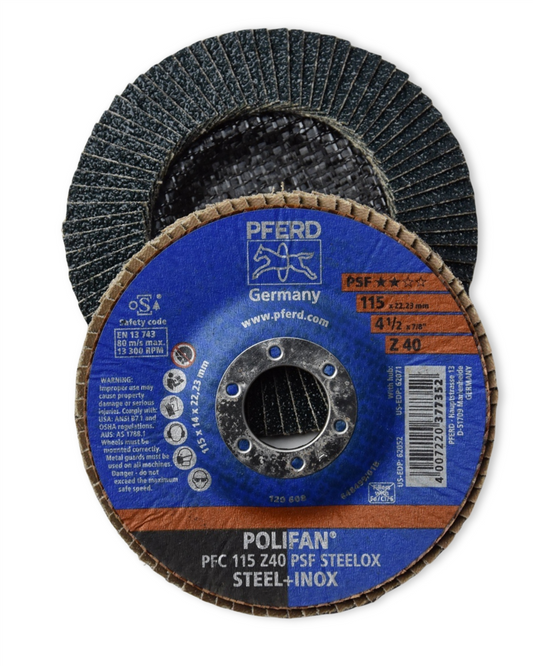

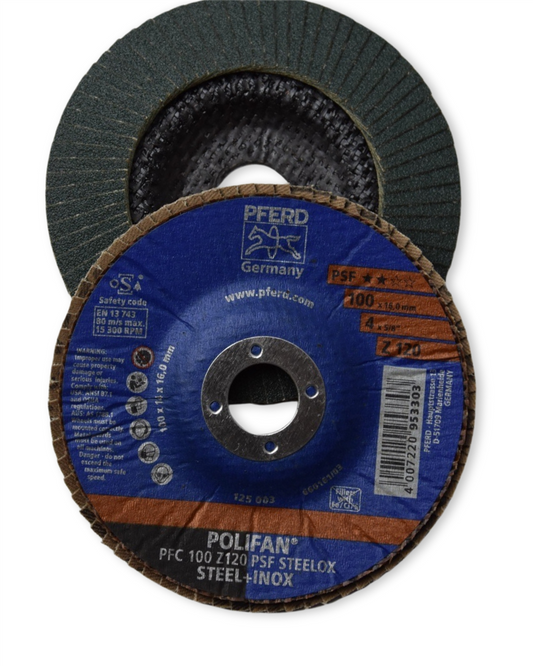

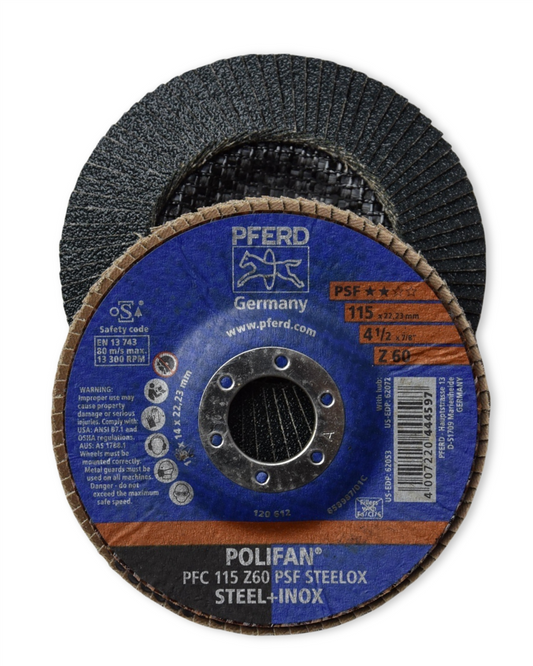

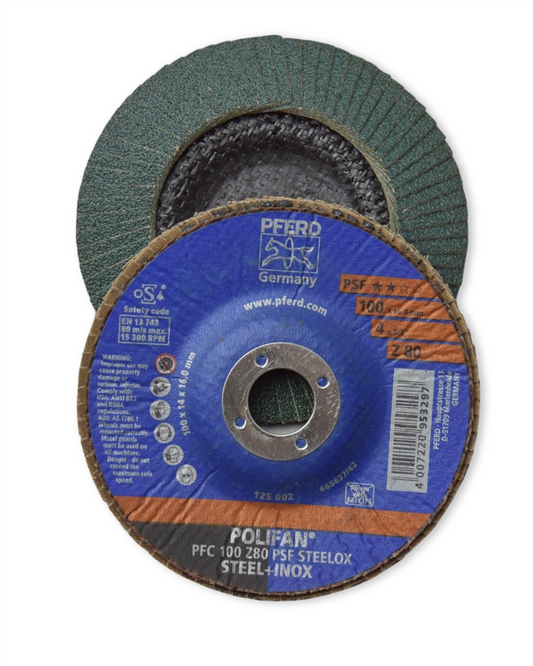

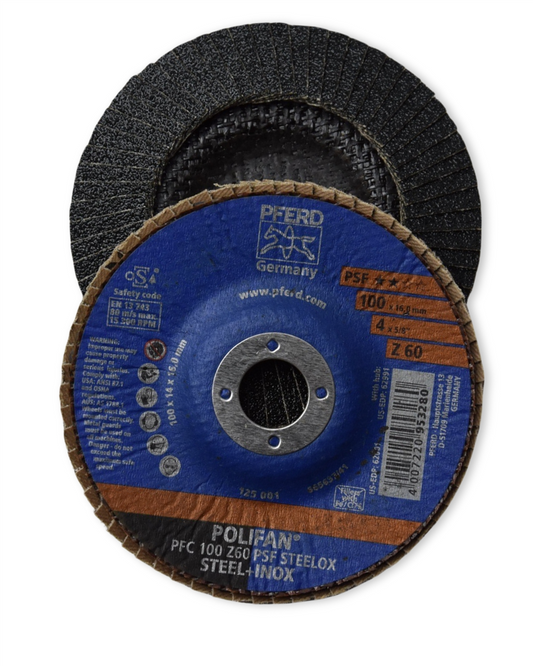

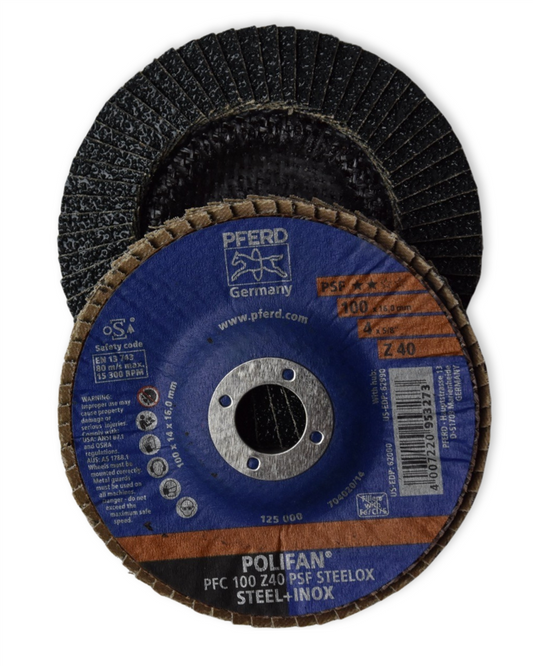

2. Know Your Discs

Not all discs are born equal. There are cutting discs for metal, diamond ones for masonry, flap discs for smoothing, and wire brushes for stripping rust. Using the wrong disc doesn’t just waste time—it’s risky business. Check the label on both the grinder and disc for size and speed rating; they must match.

Old habit to drop: forcing a worn disc to last ‘one more cut’. A fresh disc spins evenly and safely; an overused one wobbles, cracks, and can shatter mid‑spin.

3. Set Up Your Workspace

Keep the area clear. Secure the piece you’re cutting with a clamp—hands should never double as a vice. Position your body to one side of the cutting plane, not directly behind the disc. That way, if it kicks back, it’s not heading for your torso.

If you’re working outside, watch for dry grass or sawdust. Sparks can linger hot enough to smoulder. Keeping a small bucket of water or extinguisher nearby might feel cautious, but it’s smart work, not fear talking.

4. Let the Tool Do the Work

A grinder doesn’t need your muscle, just your steadiness. Light, consistent pressure wins every time. Cutting too deep or pushing too hard creates heat, jams the disc, and can kick the tool back. Think ‘glide, don’t gouge.’

“The best cuts happen when you stop fighting the tool and start trusting it.”

— Candeece H, DIY Specialist, Strathalbyn H Hardware

This line rings true for everyone—from the weekend renovator slicing tile to the full‑time fence builder reshaping steel uprights. Once you catch the rhythm, an angle grinder becomes an extension of your hand.

Common First‑Timer Mistakes (And Easy Fixes)

- Skipping the guard: It’s there for a reason. Never remove it for ‘better reach’—that’s how injuries happen.

- Wrong angle: Cutting flat creates friction; tilt around 15–30 degrees for gentler contact.

- Cutting without cooling: On thicker metal, pause between passes to prevent overheating and warping.

- Not checking sparks direction: Always aim sparks away from glass panels, cars, or anything flammable.

Then vs Now: A Quick Contrast

Back then, learning to use grinders meant trial, error, and the occasional scorch mark. Now, with community stores like ours sharing hands‑on demos and live guidance, first‑timers get results faster—and safer—than ever. It used to take hours of frustration just to straighten a warped cut; now, with the right advice, it’s five clean minutes and done.

Safety Doesn’t Kill the Fun—it Builds Confidence

You might think protective gear slows you down, but it actually does the opposite. Safe technique makes every job smoother, letting you push forward without the constant worry of mishaps. Confidence is quiet—it’s not about showing off, it’s about knowing every spark is under control.

When you finish that first project without injury, burnt workpiece, or failed blade, it hits different. That’s pride earned. That’s control taken back from chaos.

Cleaning, Storage, and Long‑Term Care

After use, disconnect the grinder, wipe it down, and store it in a dry spot away from dust and moisture. Replace discs as soon as they look worn or glazed. Once a month, check the power cord and vents—grinders pull in debris faster than most realise.

Just like sharpening your mower blades before the next lawn cut, keeping your grinder tidy ensures it’s ready when the next job calls. That small discipline adds years to your tool’s life.

Where to Go From Here

Once you master the basics, the DIY path ahead opens up: gate repairs, shed tweaks, custom brackets, outdoor furniture—anything you can picture, you can shape. It’s a surprising feeling when sparks no longer spark fear but focus.

Here’s the mic drop: Safety isn’t the opposite of skill—it’s the foundation of mastery. The person who cuts carefully cuts faster in the long run, because confidence beats chaos every time.

Stay safe, stay sharp, and keep building.

— Candeece H

Stay Connected

Follow our Facebook Page: Strathalbyn H Hardware on Facebook