How do I glue a PVC stormwater pipe together?

Share

Have you ever stood in the plumbing aisle, staring at rows of PVC pipes, connectors, and mysterious cans of “magic glue” wondering how it all comes together? Don’t worry. You’re not the only one!

Gluing a PVC stormwater pipe is easier than you think, but it does take a little know-how. So, whether you’re looking to connect a few lengths for your garden drainage or tackling something a bit more robust, grab a coffee and let’s walk through it together. You’ll feel like a seasoned DIYer by the end of this guide—promise!

First Things First: What Do You Need?

Before you pop your “can-do” DIY hat on, gather this quick list of supplies. Having everything laid out will save you from mid-project panic trips to your local hardware store (though, hey, we’ll welcome you back anytime!):

- PVC stormwater pipes in the right diameters. Double-check your measurements—you don’t want to eyeball this step.

- Matching PVC connectors or fittings (like elbows or Y-junctions).

- PVC primer and cement.

- A small paintbrush or applicator (these usually come in the primer and cement cans).

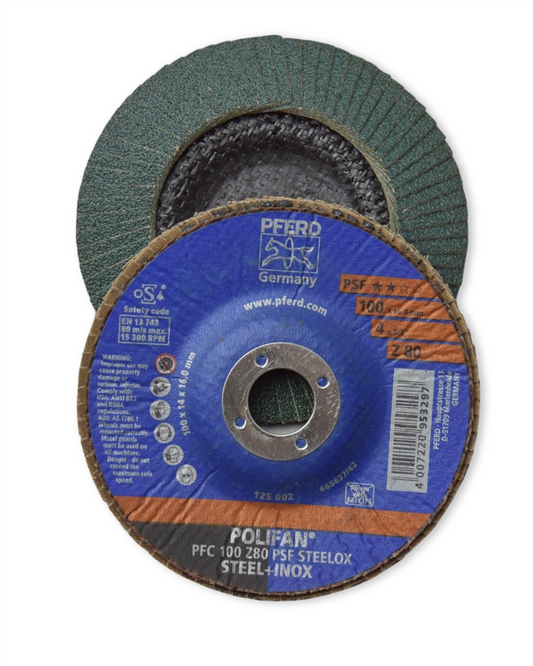

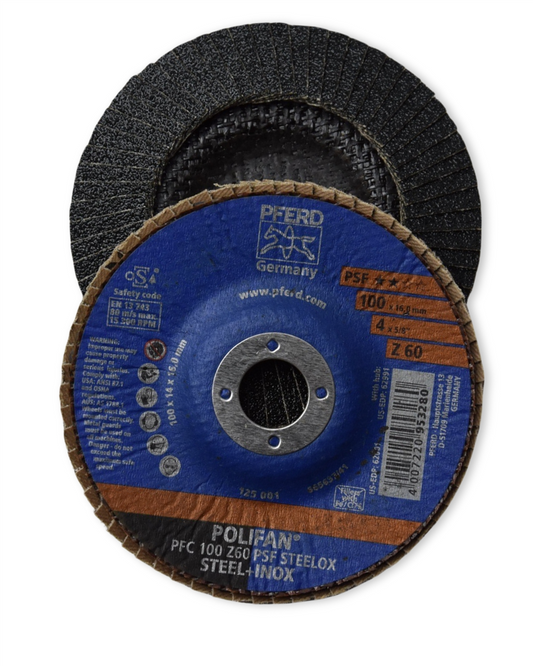

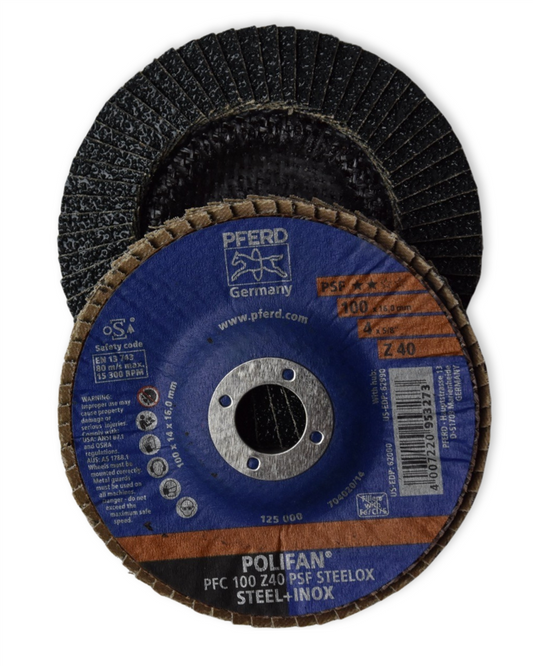

- Sandpaper or a deburring tool.

- A cloth or rag for cleaning up any messes.

- Gloves to keep the glue off your hands (trust me, it’s like trying to wipe off chewing gum).

- A flat surface and steady hands.

Step 1: The Secret to Success? Preparation

When it comes to sticking PVC together, preparation is everything. Here’s what I mean:

- Dry Fit Your Pipes: Before you even open a glue tin, make sure all your pieces fit snugly together. Push them into their joints firmly and check angles and alignment—you don’t want your water to mysteriously shoot sideways.

- Scuff the Pipe Ends: Use your sandpaper (or deburring tool, if you’ve got one handy) to lightly rough up the ends of your pipe and the insides of the fittings. You’re aiming for a surface that isn’t perfectly smooth—this helps the glue grab like Velcro.

- Clean, Clean, Clean: Wipe away any dust or dirt with your rag. PVC glue doesn’t like grime, and trust me, a dirty joint will leak faster than chocolate in the summer sun.

Step 2: Apply Primer (a.k.a. “The Undercoat”)

The primer’s job is to soften the PVC just enough for the cement to create a proper bond. Here’s the low-down on how to prime like a pro:

- Pop on your gloves—you’re about to get messy.

- Using the tiny brush the primer tin comes with, spread a thin layer of primer around the outside of the pipe end and the inside of the connector. Be generous enough to cover it evenly, but not so much that you’re dripping everything in sight.

- Let it sit for about 10 seconds. It’ll dry quickly and start working its magic.

TIP: Lay down an old towel or some cardboard to protect nearby surfaces—this glue doesn’t come out easily!

Step 3: The Glue Job

Now we’re onto the star of the show—the PVC cement. It’s essentially a super-strong adhesive designed just for PVC. Here’s how to work with it:

- Quickly apply PVC cement to both the pipe’s outer edge and the inner edge of your fitting using the built-in brush.

- Act Fast! Push the pipe into the connector firmly in one smooth motion. Wiggle it a little to spread the glue evenly, then hold it in place for about 20–30 seconds.

- Excess glue squeezing out is fine—it’s a sign you used the right amount. Wipe it off if necessary.

Step 4: Sit Back and Let It Cure

While the cement may feel “done” after a few minutes, it takes time to fully cure and form a watertight seal. Avoid running water through your masterpiece for at least 24 hours.

Top Tips for a Leak-Free Finish

- Always read the label on your cement. Use one that matches your pipe’s pressure requirements.

- Avoid gluing PVC in extreme weather—high heat or rain can mess with how the glue sets.

- Store your primer and cement cans tightly closed and upright when not in use.

Why PVC Projects Feel So Rewarding

Every time it rains and your pipes work exactly as they should, you’ll feel a little glow of pride knowing, “I did that.” And hey, if you hit a snag or need more advice, pop into Strathalbyn H Hardware. Our team is here to help—whether it’s advice, tools, or just a little confidence boost, we’ve got your back!